PREPARATION OF METAL:

Each Whitehouse piece of jewelry begins as raw material. Pure Platinum, Gold and alloy are melted to form an ingot, which is then rolled into sheets or drawn into wire. This simple form of metal working is the essential part to ensuring the integrity of Whitehouse Brothers jewelry. The basic materials of wire and sheet are used as the first step to create our die struck and handmade jewelry.

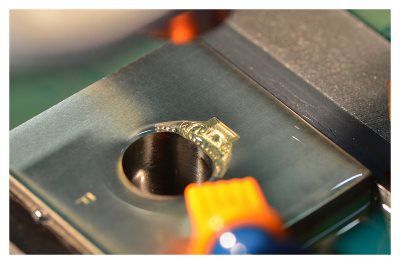

DIE STRIKING:

Every Whitehouse Brothers' piece of jewelry is manufactured using the die striking process. Hundreds of special dies have been handmade in our shop over the past 120+ years. Our precious metal sheet is forged into dies under many tons of pressure to shape and form rings the components of our engagement and wedding rings.

Whitehouse Brothers is one of few jewelry firms still manufacturing using the die striking method. This process produces a product that is far superior to the industry standard of casting. Die striking metal under extreme pressure creates a product 33% stronger and more dense than a casting. The benefit is a longer lasting product, secure settings for diamonds and gemstones, and a mirror-like luster unobtainable by other methods.

ASSEMBLY:

A Whitehouse Brothers piece of jewelry will begin to take form during hand assembly by our craftspeople. Filigree details are pierced using saw blades as small as a human hair. Each die struck component is individually polished to achieve the highest finish inside and out. Welding and soldering techniques are used to assemble the blank shape from many parts. After assembly, the blank will be filed, sanded, and polished to a fine finish, creating the palette for the diamond setter and engraver to create their masterwork.

SETTING:

Whitehouse Brothers specializes in very fine setting of diamonds and gemstones. Using small cutting tools, known as gravers, precious metal is carved to form the setting work for each stone. Carved areas around the stones are known as bright cuts. The mirror finish of a bright-cut reflects light towards your eye, enhancing the appearance of diamonds and gemstones. Fine hand setting is an integral part of producing a well-made piece of jewelry.

ENGRAVING:

Engravers finish the details of each piece of Whitehouse Brothers jewelry. The shape and style of our rings are embellished with bright cut designs and patterns by an engraving artist. Hand-cut borders around the work take shape as rows of small beads, known as milgrain. The engraver completes the artistic composition by tying all components of shape, piercing, and setting together.

FINISHING:

A final polish is applied as the last detail, bright areas are polished to the highest finish attainable. The final product is a piece of jewelry that feels and appears like no other. Whitehouse Brothers jewelry has the quality and glowing luster that only 120+ years of manufacturing fine jewelry can create.